This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Overview

A housing unit within the BRE Victorian Terrace demonstration project is being refurbished with a range of materials, products and innovations that will make it flood resilient.

The aim of the project is to raise awareness amongst contractors and householders of the most effective ways to repair and refurbish a house that has been flooded which may be at risk of being flooded again.

Earlier this year… (2016)

A number of very interesting meetings took place regarding flooding & flood resilience. The BRE and PCA attended these meetings along with Delta Membrane Systems Ltd, manufactures of structural waterproofing systems. Over a series of meetings with John O’Brien, Dr Stephen Garvin & the architectural team it was decided that the Delta System would be incorporated to contribute towards the flood resilience of the building. Specialist contractor, ProTen Services, were commissioned to carry out the installation.

Methodology

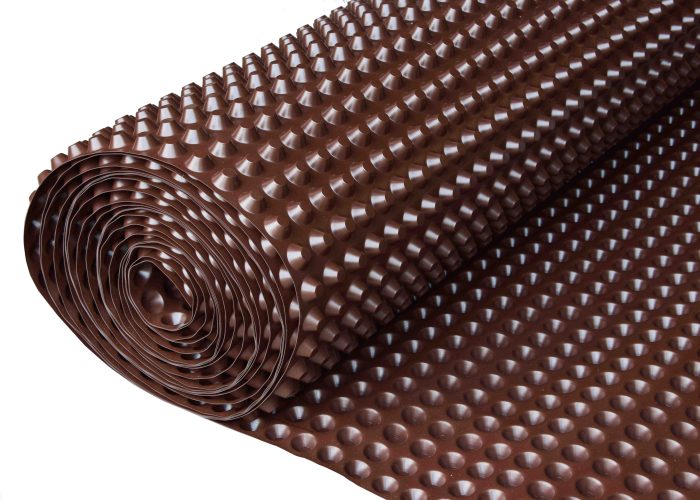

The main components of the system are the cavity drainage membranes. These are sheets manufactured from virgin HDPE which are extruded into studs which come in various depths (3mm, 8mm and 20mm). The cavity created by the studs contains between 5 and 10 Litres of space respectively. This is known as either the “Air gap” or the “Drained Cavity”, in wet situations. The cavity drain system forms a waterproof inner lining to the walls and floor whereby the water or dampness is collected and managed via. a packaged pump station.

This system is typically designed to protect against ground water ingress entering the structure behind the membrane. To make the system flood resilient Delta have re-designed the system in such a way that it will drain flood water entering the property from in front of the membrane (room side/top side). Modular drainage using 110mm drainage pipes are to be cast within the slab with upstands protruding up through the membrane and finishes, with a grated inlet flush with the finished floor. This drains any flood water to a packaged pump system and pumped to a suitable outlet.

The BRE recognises the massive disruption and the devastating effects of flooding in our homes and businesses along with Insurers who expend millions of pounds surrounding these events. The Environment Agency suggests that over 5.2 million homes in England are at risk of flooding from rivers, sea or surface water. This equates to 1 in 6 homes.

Traditionally after flooding, a loss adjuster is appointed to access the claim and damage resulting in catastrophic circumstances, this leads to the areas of the ground floor being fully stripped out and to this end the owners during this time and drying out are relocated into accommodation for many months at the cost of the Insurance industry. Flood water not only brings misery into our lives but also contamination of the fabric and internal surfaces such as masonry and can enter the structure either through openings in the fabric such as doorways and air bricks or through the ground and often independently of each other.

After a flood event, Delta may be installed and the walls lined which has two significant benefits.

1. An instant barrier is provided on the face of the wall thus contaminates are sealed allowing fast track reinstatement and reoccupation, literally in weeks instead of months.

2. The Air Gap created by the extruded studded membrane allows the walls to dry out naturally.

Whilst the above is being carried out, a sum not significant may be set aside by insurers to build in resilience.

Where solid floors are present, a drainage channel may be set into the slab and will connect to the sump and this would deal with any future affects of groundwater rising up through the structure. This can be enhanced by connecting drainage pipes through the slab that terminate at the finish floor level to further evacuate flood water. This system may also be installed within sub-floor voids.

‘The project demonstrates both resistance to flood water, as well as the resilience if water gets into the property. Along with flood resistant doors, windows and a resilient kitchen, the project will also include water resistant wall and floor membranes that channel water towards drains and sumps that disperse water quickly.

Different types of water resistant insulation will be applied including injected cavity wall insulation, thermal board and PUR spray foam. Resilient surfaces such as robust boards and cementitious tanking will also be demonstrated. The floor insulation will also be improved and different types of floor covering will be featured. The house will also have toilet and sink non-return valves and will address issues like where to place the electrics and home appliances.’ – as cited in news from the BRE Group published: 29/9/2016

Case Study Results

This project is still under construction and will be completed soon. Watch this space for updated progress.

Once completed, the home will be put to the test by flooding it with water and monitoring how quickly the home recovers and is functional again, and what damage occurs.